- Rosemount Tank Gauging

- Cameron

- Leakwise

- Siemens

- Precision Digital

- Scanjet

- Labkotec

- Enerac

- Contrec

- Berthold

- BWB Controls / Axelson

- Anderson Greenwood / AGCO

- ITT NeoDyn

- Graphic Controls

- Fuji Electric

- Fluidwell

- Xylem McDonnell Miller

- PKP Process Instrumentation

- Noshok

- Temperature Sensors

- Lauris Technologies

- Hitrol

- Radioactive Services In

- CS Instruments

- Bopp & Reuther

- RAE Systems, Inc.

- Emerson

- Supmea

- Recorders

-

Tank Gauging System

- Tank Gauging System

-

Tank Gauging System

- Rosemount 5900C Radar Level Gauge

- Rosemount 5900S Radar Level Gauge

- Rosemount 5300 GWR Level Transmitters

- Rosemount 5400 Radar Level Transmitter

- Rosemount 565/566 Multiple Spot or Average Temperature Sensor

- Rosemount 2240S Multi-input Temperature Transmitter

- Rosemount 2410 Tank Hub

- Rosemount 2160 Field Communication Unit

- Rosemount 2230 Graphical Field Display

- Rosemount 2460 System Hub

- Rosemount 3051S Pressure Transmitter

- Rosemount 2120 Vibrating Fork Liquid Level Switch

- Rosemount 2130 High Temperature Level Switch SIL2

- SmartPower Solutions

- Tank Gauging System

- Tank Gauging System

-

Tank Gauging System

- RTG 3920 Horn Antenna Gauge

- RTG 3930 Parabolic Antenna Gauge

- RTG 3950 Still-pipe Array Antenna Gauge

- RTG 3960 LPG/LNG Gauge

- DAU2100 Data Acquisition Unit

- RDU40 Remote Display Unit

- MST - Multiple Spot or Average Temperature Sensor

- WLS - Water Level Sensor

- FCU 2160 - Field Communication Unit

- FBM 2180 - Field Bus Modem

-

Radioactive Instruments

- Radioactive Instruments

- Radioactive Instruments

-

Radioactive Instruments

- BERTHOLD LB565 Microwave Radiation Brix Measurement and Concentration Measurement

- BERTHOLD LB 566/567 Microwave Analyzer (Concentration and Water Content Measurement)

- BERTHOLD Carbon Content in Fly Ash (Combustion Analyzer)

- BERTHOLD MicroPolar Moist LB 568 System Highlights (Radioactive and Microwave measurement)

- BERTHOLD LB 350 Radiometric Moisture Measurement

- Radioactive Instruments

- Radioactive Instruments

- Temperature

-

Pressure

- Precision Digital Pressure Gauges

- Pressure

- Pressure

- Pressure

- Pressure

-

Pressure

- 151P Low Differential Set Points (Explosion Proof)

- 152P Ultra Low System Pressure (Weather Proof)

- 160P Mid Range System Pressure (Weather Proof)

- 152P Ultra Low System pressure (Explosion Proof)

- 151P Low Differential Set Points (Explosion Proof)

- 160P Mid Range System Pressure (Explosion Proof)

- 162P High System Pressure (Explosion Proof)

- Pressure

- Pressure

-

Pressure

- 100P Internally Adjustable (Weather Proof)

- 101P Externally Adjustable (Weather Proof)

- 105P/105PP Minature Pressure Switch (Weather Proof)

- 110P Low Pressure Range (Weather Proof)

- 115P/115PP Built-To-Order (Weather Proof)

- 125P Higher Range Pneumatic Applications ( Weather Proof)

- 130P Adjustable Thru Port Cap-Pressure (Weather Proof)

- 131P Adjustable With Selectable Deadband-pressure (Weather Proof)

- 132P Pneumatic Or Low Impulse Hydrauic (Weather Proof)

- 142P Div 1&2 Hermetic-Ultra Low Range (Weather Proof)

- 200P Hydraulic Service-Internally Adjustable (Weather Proof)

- 201P Hydraulic Service-Externally Adjustable (Weather Proof)

- 225P High Pressure Hydraulic Applications (Weather Proof)

- 231P Adjustable Hydraulic Switch (Weather Proof)

- 232P High Pressure or High Impulse Hydraulic (Weather Proof)

- 100P Div 2/Terminal Strip (Explosion Proof)

- 100P Div 1 W/Terminal Strip ( Exposion Proof)

- 100P Div 1 & 2 hermetic (Explosion Proof)

- 110P Div 2 W/Terminal Strip- Low Range ( Explosion proof)

- 110P Div 1& 2 Hermetic- Low Range (Explosion proof)

- 112P ANSI Flanged Pessure Switch (Explosion Proof)

- 115P/115PP Build-To-Order Set Point (Explosion Proof)

- 122P CPI Pressure Switch (Explosion Proof)

- 123P Flush Welded Diaphragm (Explosion Proof)

- 125P higher Range Pneumatic Applications (Explosion Proof)

- 130P AdjustableThru Port Cap (Explosion Proof)

- 131PX Adjustable Selectable Deadband (Explosion Proof)

- 132P Universal Prssure Switch (Explosion Proof)

- 200P Div 1&2 Hermetic-hydraulic (Explosion Proof)

- 225P High Pressure hydraulic Applications (Explosion Proof)

- 231P Agjustable-Hydraulic (Explosion Proof)

- 232P High Pressure-Hydraulic (Explosion Proof)

-

Pressure

- 142P Ultra Low Vacuum (Explosion Proof)

- 142P Ultra LowVacuum (Weather Proof)

- 180P High System Pressure (Weather Proof)

- 181P Compact Vacuum Switch (Weather Proof)

- 182P Adjustabe Thru Port Cap (Weather Proof)

- 142P Ultra Low Vacuum (Explosion Proof)

- 181P Compact Vacuum (Explosion Proof)

- 182P Adjustable Thru Port Cap-Vacuum (Explosion Proof)

- Pressure

- Pressure

- Pressure

- Pressure

- Pressure

- Pressure

-

Flow

-

Flow

- Paddle Type Flow Switch

- Paddle type flow switch with cable connection

- Paddle-bellows flow switch for liquids, with variable switching point

- Paddle-bellows flow meter and switch for liquids

- Flap Flowmeter and switch for low viscosity liquids

- Flap Flowmeter

- Paddle-bellows type flow switch with micro switch

-

Flow

- Flow Indicator with Wiper

- Rotor-type Flow Indicator

- Flow Indicator with Turbine

- Flow Indicator with Flanges

- Flow Indicator with Flap and Scale

- Ball type Flow Indicator

- Flow Indicator with Threaded Connection

- DG11 Flow Sight Glass with Flanged Connections

- Miniature Variable Area Flow meter and Switch

- Variable area flowmeter and switch with glass measuring tube

- Plastic Variable Area Flowmeter

- Float-Type Flow Meter For low flow volumes Compact construction

- Variable Area Flowmeter With Flange Connection, Insensitive To Viscosity Changes

- Piston Type Flow Switch for Low Flow Applications

- Flow

- Flow

- Flow

-

Flow

- SIEMENS SITRANS FUS 1010 (Standard) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUE 1010 (Energy) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUP 1010 (Portable) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUG 1010 (Gas) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUT 1010 (Liquid) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUT 1010 (Gas) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FST 020 (Basic) Ultrasonic clamp-on flowmeters

-

Flow

- SIEMENS SITRANS FM MAG 3100 Flow Meter - Electromagnetic (sensor)

- SIEMENS SITRANS FM MAG 5100W Flow Meter - Electromagnetic (sensor)

- SIEMENS SITRANS FM MAG 1100 F Electromagnetic Flowmeter

- SIEMENS SITRANS FM MAG 1100 Electromagnetic Flowmeter

- SIEMENS SITRANS FM MAG 3100P Electromagnetic Flowmeter (Sensor)

- SIEMENS SITRANS FM MAG 5100 Ex d Electromagnetic Flowmeter(transmitter)

- SIEMENS SITRANS FM MAG 6000 Electromagnetic Flowmeter (transmitter)

- SIEMENS SITRANS FM MAG 6000 I/6000 I Ex de ELectromagnetic Flowmeter (transmitter)

- SIEMENS SITRANS FM Verificator Electromagnetic Flowmeter (Equipment tester for flowmeter)

- Flow

-

Flow

- SIEMENS SITRANS FCT 030 Coriolis/Density Flowmeter (Transmitter)

- SIEMENS SITRANS FC MASS 6000 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC MASS 6000 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SIFLOW FC 070 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC S400 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC S200 Ex d Coriolis/Density Flowmeter(Sensor)

- SIEMENS SITRANS FC MC 2 DN 50-150/ DN 20-80 (Hygienic) Ex d Coriolis/Density Flowmeter(sensor)

- SIEMENS SIEMENS SITRANS FC MASS 2100 DI 3-40 Ex d Coriolis/Density Flowmeter(sensor)

- SIEMENS SITRANS FC300 DN 4 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC MASS 2100 DI 1.5 Ex d Coriolis/Density Flowmeter(sensor)

- Flow

-

Flow

- Liquid Flow Switches

- General Purpose Liquid Flow Switches FS 251 and FS 254

- FS 4-3T General Purpose Liquid Flow Switches

- FS 4-3 General Purpose Liquid Flow Switches

- FS 6-W High Sensitivity Liquid Flow Switches

- FS 1-W High Sensitivity Liquid Flow Switches

- FS 5 General Purpose Liquid Flow Switches

- FS 6 High Sensitivity Liquid Flow Switches

- FS 7-4E General Purpose Liquid Flow Switches

- FS 7-4 Industrial Liquid Flow Switches

- FS 7-4W Industrial Liquid Flow Switches

- FS 8-W Industrial Liquid Flow Switches

- Flow

- SIEMENS SITRANS DP Flow Transmitter

- Flow

- Flow

- Flow

-

Flow

- Low Water Cut off- Mechanical for Steam Boiler

- RB-122-E-Low Water Cut-Off

- RB-24E-Low Water Cut-Off

- RBT-3000 LWCO and Fuel Economizer

- RS-1-HP High Pressure Remote Sensor

- RS-1-LP Low Pressure Remote Sensor

- Series 21/221 Make-Up Water Feeders

- Series 25-A Make-Up Water Feeder

- Series 27-W Valve

- Series 47-2/247-2 Mechanical Water Feeder/LWCO

- Series 42S LWCO/Pump Controllers

- Series 47/247 Water Feeders

- Series 51/51-2 Mechanical Water Feeders/ LWCO

- Series 53/53-2 Mechanical Water Feeders/ LWCO

- Flow

- Cameron Flow Analysers

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Restriction Orifice

- Flow

- Flow

- Flow

- Electromagnetic Flow Meters

- Flow

- Cavitating Venturi

- Flow

- Flow

- Flow

- Flow

- Paddle Switches

- Flow

- Flow

- Bopp and Reuther coriolis flow meter

-

Flow

- Level

- Oil / Sludge Alarm

-

Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F050 Pressure indicator with very large digits with on-screen measuring units

- Fluidwell D050 Pressure indicator with very large digits

- Fluidwell F151 Dual input pressure indicator with separate engineering units for each input

- Fluidwell F053 Pressure monitor with one high / low alarm output

- Fluidwell F153 Pressure monitor with high / low alarms and analog outputs

- Fluidwell D053 Pressure monitor with one high / low alarm output

- Fluidwell F143 Temperature monitor with high / low alarms and analog outputs

-

Panel / Process Meters

- Fluidwell F040 Temperature indicator with very large digits

- Fluidwell D040 Temperature indicator with very large digits

- Fluidwell F141 Dual input temperature indicator with separate engineering units for each input

- Fluidwell F043 Temperature monitor with one high / low alarm output

- Fluidwell D043 Temperature monitor with one high / low alarm output

-

Panel / Process Meters

- Fluidwell F090 General purpose indicator input loop powered with very large digits

- Fluidwell D090 General purpose indicator input loop powered with very large digits

- Fluidwell F193 Modbus display with alarms, control and analog outputs

- Fluidwell F195 Valve Position Indicator VPI for hydraulic systems

- Fluidwell F197 Set-point generator with temperature input, alarms and analog outputs

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F126-EL Flow computer with temperature compensation for corrected liquid volume

- Fluidwell F126-EG Flow computer with temp & pressure compensation for corrected gas volume

- Fluidwell F127 Differential flow computer with temperature compensation for corrected liquid

- Fluidwell F114 Ratio monitor / totalizer with high/low alarms and analog outputs

- Fluidwell F116 Differential / sum flow computer with analog and pulse outputs

-

Panel / Process Meters

- Fluidwell F070 Level indicator with very large digits

- Fluidwell D070 Level indicator with very large digits

- Fluidwell F073 Level monitor with one high / low alarm output

- Fluidwell F077 Level monitor with linearization and one high / low alarm output

- Fluidwell F170 Level monitor with high / low alarms and analog outputs

- Fluidwell F173 Level monitor with linearization, high / low alarms and analog outputs

- Fluidwell D073 Level monitor with one high / low alarm output

- Fluidwell D077 Level monitor with linearization and one high / low alarm output

- Fluidwell F074 Level / pump controller with one control output

- Fluidwell D074 Level / pump controller with one control output

- Panel / Process Meters

- Flow Rate / Totalisers

- Panel / Process Meters

-

Panel / Process Meters

- PD6060: PROVU Dual-Input Process Meter

- PD6080: PROVU Modbus Scanner with Dual Analog Inputs

- PD6081: PROVU Feet & Inches Modbus Scanner with Dual Analog Inputs

- PD6088: PROVU Modbus Scanner

- PD6089: PROVU Feet & Inches Modbus Scanner

- PD6100: PROVU Strain Gauge, Load Cell & mV Meter

- PD603: Sabre P Low-Cost Process Meter

- PD865 Snooper Modbus Serial Input Meter

- PD6000: PROVU Process Meter

- Panel / Process Meters

-

Panel / Process Meters

- PDA 2301-2322: Economical Plastic NEMA 4X Enclosures for 1/8 DIN Instruments

- PDA2407-2415: Plastic NEMA 4X Enclosures

- PDA2501-2522: Plastic NEMA 4X Enclosures

- PDA2601-2622: Stainless Steel NEMA 4X Enclosures

- PDA2701-2722: Steel NEMA 4 Enclosures

- PDA2801-2821: Low-Cost Plastic NEMA 4X Enclosure

- PDA2901: NEMA 4X Enclosures for ConsoliDator

- PDA3407-3414: Economical Plastic Fully Sealed Enclosures

- Panel / Process Meters

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F030 Field mount - Batch controller with one-stage control

- Fluidwell F130 Field mount - Batch controller with two-stage control and pulse output

- Fluidwell F131 Batch controller with 2-stage control, pulse & analog o/p in relation to flow rate

- Fluidwell F132 Field mount-Batch controller with two-stage control and receipt printer driver

- Fluidwell F136 Batch controller with 2-stage control, pulse & analog o/p in relation to process

- Fluidwell D030 DIN Panel mount - Batch controller with one stage control

- Fluidwell N410 DIN Panel mount - Batch controller

- Fluidwell 310 Batch controller with numerical keypad and two-stage control

- Fluidwell 313 Batch controller with numerical keypad and direct ticket printing

- Fluidwell 320 Batch controller with numerical keypad, multiple preset values

- Fluidwell 326 Tanker loading computer with numerical keypad

- Fluidwell 330 Dual batch controller with numerical keypad

- Fluidwell F133 Delivery controller / Dispenser with pump start and valve control

-

Panel / Process Meters

- Fluidwell F010 Flow rate indicator with very large digits

- Fluidwell F011 Totalizer with on-screen measuring units

- Fluidwell F012 Flow rate indicator / totalizer displays flow rate and total simultaneously

- Fluidwell D010 DIN Panel mount - Flow rate indicator with very large digits

- Fluidwell D011 DIN Panel mount - Totalizer with all-weatherproof front enclosure

- Fluidwell D012 Flow rate indicator / totalizer displays flow rate and total simultaneously

- Fluidwell F014 Flow rate indicator / totalizer with pulse output

- Fluidwell F016 Flow rate indicator / totalizer with linearization and pulse output

- Fluidwell F110 Flow rate indicator / totalizer with analog and pulse outputs

- Fluidwell F111 Dual input flow rate indicator / totalizer with two pulse outputs

- Fluidwell F115 Bi-directional flow rate indicator/totalizer with analog, pulse & flow direction o/p

- Fluidwell D014 Flow rate indicator / totalizer with pulse signal output

- Fluidwell F013 Flow rate monitor/totalizer with one high/low alarm output

- Fluidwell F113 Flow rate monitor / totalizer with high/low alarms, analog & pulse output

- Fluidwell F117 Totalizer monitor with high / low totalizer alarms and analog output

- Fluidwell F118 Flow rate monitor/totalizer with linearization, high/low alarms, analog & pulse o/p

- Fluidwell D013 DIN Panel mount - Flow rate monitor / totalizer with high / low alarm output

- Fluidwell F112 Flow rate indicator / totalizer with linearization, analog and pulse outputs

- Fluidwell D016 Flow rate indicator / totalizer with linearization and pulse signal output

- Fluidwell F018 Flow rate monitor/totalizer with linearization,pulse/alarm & analog o/p and HART

- Fluidwell E018 Explosion proof-Flow rate/totalizer with HART Communication

- Fluidwell E110 Flow rate indicator / totalizer with analog and pulse signal outputs

- Fluidwell E112 Flow rate indicator / totalizer with linearization, analog and pulse outputs

- Fluidwell F120 Flow rate controller with analog control output and high / low alarms

- Fluidwell F124 Ratio controller with analog control output and high / low alarms

- Fluidwell E115 Explosion-Proof Bi-directional Flow rate Indicator / Totalizer

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Inst Valves - Manifolds

- Tank Cleaning

- Process Protection

- Valve Positioners

- Analysers

- Signal Generator

- 4-20mA Set-Point Generator

- Large Display Field Mount Indicators

- Control Stations

- Lithium Battery

- Dosimeter

- Calibrator

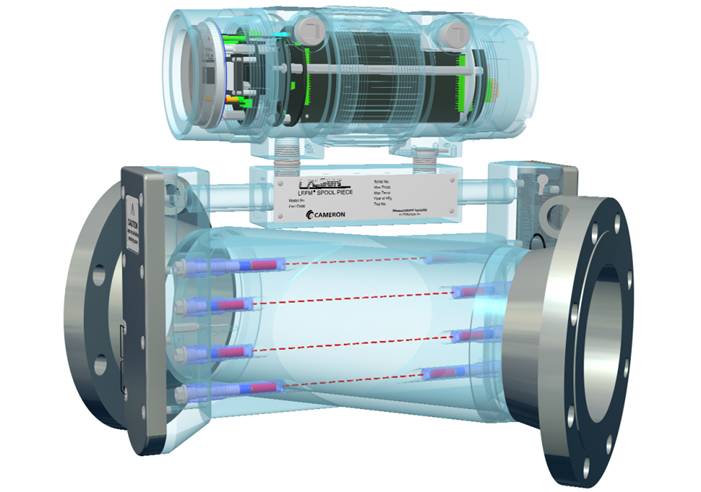

Custody Grade Ultrasonic Flow Meter

The Caldon™ line of ultrasonic meters uses advanced m transit time ultrasonic technology to provide measurements based on the movement of sound waves through fluids. The Caldon ultrasonic meters from Cameron offers excellent solutions for demanding high performance applications, ranging from clean liquids to mining slurries in both the nuclear and oil and gas industries.

Cameron's CALDON® LEFM® 280Ci full bore ultrasonic flow meter can be used on crude oils and refined products in single or multi-product pipelines. The operating Reynolds numbers should be above 8000 at all times to ensure maximum performance. The eight chordal path design of the LEFM 280Ci ultrasonic flow meters resists installation errors better than any other ultrasonic meter.

Cameron's CALDON® LEFM® 280Ci full bore ultrasonic flow meter can be used on crude oils and refined products in single or multi-product pipelines. The operating Reynolds numbers should be above 8000 at all times to ensure maximum performance.

The eight chordal path design of the LEFM 280Ci ultrasonic flow meters resists installation errors better than any other ultrasonic meter. The cross plane acoustic paths make the meter immune to the effects of swirl and eliminate the need for an upstream flow conditioner. The effects of swirl on the four paths in one plane are equal and opposite to the effects of swirl on the four paths in the second plane. When the velocity readings from all eight paths are averaged together any effects from swirl are cancelled out. The design also minimizes the requirement for upstream/downstream pipe runs. The elimination of a flow conditioner and the need for shorter lengths of upstream pipe reduce the installed cost for the LEFM 280Ci. In addition, the elimination of a flow conditioner means lower overall pressure loss which equates to annual savings in pumping costs.

Cameron was the first company to develop an ultrasonic flow meter, the LEFM 280CiLT, for dynamic custody transfer of LNG. The LEFM 280CiLT low temperature ultrasonic flow meter has been voted the 2010 Innovation Award by the readers of Flow Control magazine. The LEFM 280CiLT meter offers many benefits for measuring LNG. The major advantage is the 8-path design. The two-plane arrangement of the eight acoustic paths makes the meter insensitive to velocity profile asymmetry and swirl.

Cameron was the first company to develop an ultrasonic flow meter, the LEFM 280CiLT, for dynamic custody transfer of LNG. The LEFM 280CiLT low temperature ultrasonic flow meter has been voted the 2010 Innovation Award by the readers of Flow Control magazine. The LEFM 280CiLT meter offers many benefits for measuring LNG. The major advantage is the 8-path design. The two-plane arrangement of the eight acoustic paths makes the meter insensitive to velocity profile asymmetry and swirl. The LEFM 280CiLT does not require a flow conditioner and needs minimal straight runs of pipe upstream/downstream of the meter. In 2005 Cameron supplied an LEFM 280CiLT to a joint ExxonMobil/ConocoPhillips project designed to assess flow technologies for LNG projects. These tests confirmed the effect of swirl was equal and symmetrical between the two planes and that averaging the velocities between the 8-paths eliminated any bias due to swirl.

Being able to measure LNG with higher accuracy than traditional methods using the LEFM 280CiLT can result in real savings. The monetary value of the LNG on an average tanker is approximately $31.9MM, based on an average tanker size of 266K cubic meters and an April 2010 estimated value of LNG of $120/cubic meter. An overall improvement of just 0.10% in uncertainty by using the LEFM280CiLT can result in a potential savings of $31.9K per tanker load. The elimination of a flow conditioner lowers overall pressure loss which equates to additional annual savings in pumping costs or faster ship loading times.

Specifications

§ Full bore meter designed specifically for dynamic custody transfer of LNG

§ Calibration methodology and uncertainty verified by NMi

§ Available in 8-inch to 24-inch sizes

§ Uncertainty of +/-0.16 to +/-0.18%

§ OIML R117 (0.3 Class)

Measuring oils having high viscosity and/or low flow conditions may involve operating at Reynolds numbers below 8000, in the laminar and transition flow regimes. Full bore ultrasonic flow meter performance has traditionally degraded for Reynolds numbers below 8000 because the liquid velocity profile erratically switches between laminar and turbulent characteristics. Cameron\\\'s CALDON® LEFM® 280CiRN ultrasonic flow meter with a reduced bore, modeled after flow nozzle technology, in which the liquid velocity profile is stabilized in the throat by forces much larger than the forces imposed by fluid viscosity

Measuring oils having high viscosity and/or low flow conditions may involve operating at Reynolds numbers below 8000, in the laminar and transition flow regimes. Full bore ultrasonic flow meter performance has traditionally degraded for Reynolds numbers below 8000 because the liquid velocity profile erratically switches between laminar and turbulent characteristics. Cameron's CALDON® LEFM® 280CiRN ultrasonic flow meter with a reduced bore, modeled after flow nozzle technology, in which the liquid velocity profile is stabilized in the throat by forces much larger than the forces imposed by fluid viscosity. The meter design stabilizes the flow profile while preventing boundary layer separation under all operating conditions, greatly improving performance.

The eight path design of the LEFM 280CiRN ultrasonic flow meters resists installation errors better than any other ultrasonic meter. The cross plane acoustic paths make the meter immune to the effects of swirl and eliminate the need for an upstream flow conditioner. The effects of swirl on the four paths in one plane are equal and opposite to the effects of swirl on the four paths in the second plane. When the velocity readings from all eight paths are averaged together any effects from swirl are cancelled out. The design also minimizes the requirement for upstream/downstream pipe runs.

The elimination of a flow conditioner and the need for shorter lengths of upstream pipe reduce the installed cost for the LEFM 280CiRN. In addition, the elimination of a flow conditioner means lower overall pressure loss which equates to annual savings in pumping costs.

The LEFM 280CiRN has improved repeatability compared to standard full bore meters and may also be considered for applications when the meter is to be verified in-situ using a prover to reduce the number of runs required.

Specifications

§ Reduced-bore design for high performance under laminar, transition or turbulent flow

§ Excellent repeatability that reduces the number of runs required to verify the meter in-situ with a prover

§ Electronics that can be integrally or remote pipe mounted

§ Available in 6" to 36" sizes

§ +/-0.12% linearity over 15:1 nominal flow range for all sizes

§ No limit on operating Reynolds number

§ OIML R117 (0.3 Class)

Cameron's CALDON® 380Ci ultrasonic gas flow meter has Cameron's unique eight-path, dual-plane, cross-path design. Cameron has done extensive testing to prove this meter design is immune from the effects of swirl and velocity profile asymmetry. The 380Ci requires a very small installation footprint and does not require a flow conditioner.

Cameron's CALDON® 380Ci ultrasonic gas flow meter has Cameron's unique eight-path, dual-plane, cross-path design. Cameron has done extensive testing to prove this meter design is immune from the effects of swirl and velocity profile asymmetry. The 380Ci requires a very small installation footprint and does not require a flow conditioner. The 380Ci gas flow meter is available for pipe sizes 6" and larger and is typically used in custody transfer and other fiscal applications.

Specifications

§ Eight-path, dual-plane configuration

§ Sealed transducer housing design

§ Proprietary coating

§ LEFMLink and 2G eCheck software

§ Compact installation and reduction in CAPEX by reducing the length of required upstream pipe and eliminating a flow conditioner

§ Available in various materials of construction

§ Design that is configurable to accept various end connections requirements

§ Wide range of input/output options