- Rosemount Tank Gauging

- Cameron

- Leakwise

- Siemens

- Precision Digital

- Scanjet

- Labkotec

- Enerac

- Contrec

- Berthold

- BWB Controls / Axelson

- Anderson Greenwood / AGCO

- ITT NeoDyn

- Graphic Controls

- Fuji Electric

- Fluidwell

- Xylem McDonnell Miller

- PKP Process Instrumentation

- Noshok

- Temperature Sensors

- Lauris Technologies

- Hitrol

- Radioactive Services In

- CS Instruments

- Bopp & Reuther

- RAE Systems, Inc.

- Emerson

- Supmea

- Recorders

-

Tank Gauging System

- Tank Gauging System

-

Tank Gauging System

- Rosemount 5900C Radar Level Gauge

- Rosemount 5900S Radar Level Gauge

- Rosemount 5300 GWR Level Transmitters

- Rosemount 5400 Radar Level Transmitter

- Rosemount 565/566 Multiple Spot or Average Temperature Sensor

- Rosemount 2240S Multi-input Temperature Transmitter

- Rosemount 2410 Tank Hub

- Rosemount 2160 Field Communication Unit

- Rosemount 2230 Graphical Field Display

- Rosemount 2460 System Hub

- Rosemount 3051S Pressure Transmitter

- Rosemount 2120 Vibrating Fork Liquid Level Switch

- Rosemount 2130 High Temperature Level Switch SIL2

- SmartPower Solutions

- Tank Gauging System

- Tank Gauging System

-

Tank Gauging System

- RTG 3920 Horn Antenna Gauge

- RTG 3930 Parabolic Antenna Gauge

- RTG 3950 Still-pipe Array Antenna Gauge

- RTG 3960 LPG/LNG Gauge

- DAU2100 Data Acquisition Unit

- RDU40 Remote Display Unit

- MST - Multiple Spot or Average Temperature Sensor

- WLS - Water Level Sensor

- FCU 2160 - Field Communication Unit

- FBM 2180 - Field Bus Modem

-

Radioactive Instruments

- Radioactive Instruments

- Radioactive Instruments

-

Radioactive Instruments

- BERTHOLD LB565 Microwave Radiation Brix Measurement and Concentration Measurement

- BERTHOLD LB 566/567 Microwave Analyzer (Concentration and Water Content Measurement)

- BERTHOLD Carbon Content in Fly Ash (Combustion Analyzer)

- BERTHOLD MicroPolar Moist LB 568 System Highlights (Radioactive and Microwave measurement)

- BERTHOLD LB 350 Radiometric Moisture Measurement

- Radioactive Instruments

- Radioactive Instruments

- Temperature

-

Pressure

- Precision Digital Pressure Gauges

- Pressure

- Pressure

- Pressure

- Pressure

-

Pressure

- 151P Low Differential Set Points (Explosion Proof)

- 152P Ultra Low System Pressure (Weather Proof)

- 160P Mid Range System Pressure (Weather Proof)

- 152P Ultra Low System pressure (Explosion Proof)

- 151P Low Differential Set Points (Explosion Proof)

- 160P Mid Range System Pressure (Explosion Proof)

- 162P High System Pressure (Explosion Proof)

- Pressure

- Pressure

-

Pressure

- 100P Internally Adjustable (Weather Proof)

- 101P Externally Adjustable (Weather Proof)

- 105P/105PP Minature Pressure Switch (Weather Proof)

- 110P Low Pressure Range (Weather Proof)

- 115P/115PP Built-To-Order (Weather Proof)

- 125P Higher Range Pneumatic Applications ( Weather Proof)

- 130P Adjustable Thru Port Cap-Pressure (Weather Proof)

- 131P Adjustable With Selectable Deadband-pressure (Weather Proof)

- 132P Pneumatic Or Low Impulse Hydrauic (Weather Proof)

- 142P Div 1&2 Hermetic-Ultra Low Range (Weather Proof)

- 200P Hydraulic Service-Internally Adjustable (Weather Proof)

- 201P Hydraulic Service-Externally Adjustable (Weather Proof)

- 225P High Pressure Hydraulic Applications (Weather Proof)

- 231P Adjustable Hydraulic Switch (Weather Proof)

- 232P High Pressure or High Impulse Hydraulic (Weather Proof)

- 100P Div 2/Terminal Strip (Explosion Proof)

- 100P Div 1 W/Terminal Strip ( Exposion Proof)

- 100P Div 1 & 2 hermetic (Explosion Proof)

- 110P Div 2 W/Terminal Strip- Low Range ( Explosion proof)

- 110P Div 1& 2 Hermetic- Low Range (Explosion proof)

- 112P ANSI Flanged Pessure Switch (Explosion Proof)

- 115P/115PP Build-To-Order Set Point (Explosion Proof)

- 122P CPI Pressure Switch (Explosion Proof)

- 123P Flush Welded Diaphragm (Explosion Proof)

- 125P higher Range Pneumatic Applications (Explosion Proof)

- 130P AdjustableThru Port Cap (Explosion Proof)

- 131PX Adjustable Selectable Deadband (Explosion Proof)

- 132P Universal Prssure Switch (Explosion Proof)

- 200P Div 1&2 Hermetic-hydraulic (Explosion Proof)

- 225P High Pressure hydraulic Applications (Explosion Proof)

- 231P Agjustable-Hydraulic (Explosion Proof)

- 232P High Pressure-Hydraulic (Explosion Proof)

-

Pressure

- 142P Ultra Low Vacuum (Explosion Proof)

- 142P Ultra LowVacuum (Weather Proof)

- 180P High System Pressure (Weather Proof)

- 181P Compact Vacuum Switch (Weather Proof)

- 182P Adjustabe Thru Port Cap (Weather Proof)

- 142P Ultra Low Vacuum (Explosion Proof)

- 181P Compact Vacuum (Explosion Proof)

- 182P Adjustable Thru Port Cap-Vacuum (Explosion Proof)

- Pressure

- Pressure

- Pressure

- Pressure

- Pressure

- Pressure

-

Flow

-

Flow

- Paddle Type Flow Switch

- Paddle type flow switch with cable connection

- Paddle-bellows flow switch for liquids, with variable switching point

- Paddle-bellows flow meter and switch for liquids

- Flap Flowmeter and switch for low viscosity liquids

- Flap Flowmeter

- Paddle-bellows type flow switch with micro switch

-

Flow

- Flow Indicator with Wiper

- Rotor-type Flow Indicator

- Flow Indicator with Turbine

- Flow Indicator with Flanges

- Flow Indicator with Flap and Scale

- Ball type Flow Indicator

- Flow Indicator with Threaded Connection

- DG11 Flow Sight Glass with Flanged Connections

- Miniature Variable Area Flow meter and Switch

- Variable area flowmeter and switch with glass measuring tube

- Plastic Variable Area Flowmeter

- Float-Type Flow Meter For low flow volumes Compact construction

- Variable Area Flowmeter With Flange Connection, Insensitive To Viscosity Changes

- Piston Type Flow Switch for Low Flow Applications

- Flow

- Flow

- Flow

-

Flow

- SIEMENS SITRANS FUS 1010 (Standard) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUE 1010 (Energy) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUP 1010 (Portable) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUG 1010 (Gas) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUT 1010 (Liquid) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUT 1010 (Gas) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FST 020 (Basic) Ultrasonic clamp-on flowmeters

-

Flow

- SIEMENS SITRANS FM MAG 3100 Flow Meter - Electromagnetic (sensor)

- SIEMENS SITRANS FM MAG 5100W Flow Meter - Electromagnetic (sensor)

- SIEMENS SITRANS FM MAG 1100 F Electromagnetic Flowmeter

- SIEMENS SITRANS FM MAG 1100 Electromagnetic Flowmeter

- SIEMENS SITRANS FM MAG 3100P Electromagnetic Flowmeter (Sensor)

- SIEMENS SITRANS FM MAG 5100 Ex d Electromagnetic Flowmeter(transmitter)

- SIEMENS SITRANS FM MAG 6000 Electromagnetic Flowmeter (transmitter)

- SIEMENS SITRANS FM MAG 6000 I/6000 I Ex de ELectromagnetic Flowmeter (transmitter)

- SIEMENS SITRANS FM Verificator Electromagnetic Flowmeter (Equipment tester for flowmeter)

- Flow

-

Flow

- SIEMENS SITRANS FCT 030 Coriolis/Density Flowmeter (Transmitter)

- SIEMENS SITRANS FC MASS 6000 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC MASS 6000 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SIFLOW FC 070 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC S400 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC S200 Ex d Coriolis/Density Flowmeter(Sensor)

- SIEMENS SITRANS FC MC 2 DN 50-150/ DN 20-80 (Hygienic) Ex d Coriolis/Density Flowmeter(sensor)

- SIEMENS SIEMENS SITRANS FC MASS 2100 DI 3-40 Ex d Coriolis/Density Flowmeter(sensor)

- SIEMENS SITRANS FC300 DN 4 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC MASS 2100 DI 1.5 Ex d Coriolis/Density Flowmeter(sensor)

- Flow

-

Flow

- Liquid Flow Switches

- General Purpose Liquid Flow Switches FS 251 and FS 254

- FS 4-3T General Purpose Liquid Flow Switches

- FS 4-3 General Purpose Liquid Flow Switches

- FS 6-W High Sensitivity Liquid Flow Switches

- FS 1-W High Sensitivity Liquid Flow Switches

- FS 5 General Purpose Liquid Flow Switches

- FS 6 High Sensitivity Liquid Flow Switches

- FS 7-4E General Purpose Liquid Flow Switches

- FS 7-4 Industrial Liquid Flow Switches

- FS 7-4W Industrial Liquid Flow Switches

- FS 8-W Industrial Liquid Flow Switches

- Flow

- SIEMENS SITRANS DP Flow Transmitter

- Flow

- Flow

- Flow

-

Flow

- Low Water Cut off- Mechanical for Steam Boiler

- RB-122-E-Low Water Cut-Off

- RB-24E-Low Water Cut-Off

- RBT-3000 LWCO and Fuel Economizer

- RS-1-HP High Pressure Remote Sensor

- RS-1-LP Low Pressure Remote Sensor

- Series 21/221 Make-Up Water Feeders

- Series 25-A Make-Up Water Feeder

- Series 27-W Valve

- Series 47-2/247-2 Mechanical Water Feeder/LWCO

- Series 42S LWCO/Pump Controllers

- Series 47/247 Water Feeders

- Series 51/51-2 Mechanical Water Feeders/ LWCO

- Series 53/53-2 Mechanical Water Feeders/ LWCO

- Flow

- Cameron Flow Analysers

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Restriction Orifice

- Flow

- Flow

- Flow

- Electromagnetic Flow Meters

- Flow

- Cavitating Venturi

- Flow

- Flow

- Flow

- Flow

- Paddle Switches

- Flow

- Flow

- Bopp and Reuther coriolis flow meter

-

Flow

- Level

- Oil / Sludge Alarm

-

Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F050 Pressure indicator with very large digits with on-screen measuring units

- Fluidwell D050 Pressure indicator with very large digits

- Fluidwell F151 Dual input pressure indicator with separate engineering units for each input

- Fluidwell F053 Pressure monitor with one high / low alarm output

- Fluidwell F153 Pressure monitor with high / low alarms and analog outputs

- Fluidwell D053 Pressure monitor with one high / low alarm output

- Fluidwell F143 Temperature monitor with high / low alarms and analog outputs

-

Panel / Process Meters

- Fluidwell F040 Temperature indicator with very large digits

- Fluidwell D040 Temperature indicator with very large digits

- Fluidwell F141 Dual input temperature indicator with separate engineering units for each input

- Fluidwell F043 Temperature monitor with one high / low alarm output

- Fluidwell D043 Temperature monitor with one high / low alarm output

-

Panel / Process Meters

- Fluidwell F090 General purpose indicator input loop powered with very large digits

- Fluidwell D090 General purpose indicator input loop powered with very large digits

- Fluidwell F193 Modbus display with alarms, control and analog outputs

- Fluidwell F195 Valve Position Indicator VPI for hydraulic systems

- Fluidwell F197 Set-point generator with temperature input, alarms and analog outputs

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F126-EL Flow computer with temperature compensation for corrected liquid volume

- Fluidwell F126-EG Flow computer with temp & pressure compensation for corrected gas volume

- Fluidwell F127 Differential flow computer with temperature compensation for corrected liquid

- Fluidwell F114 Ratio monitor / totalizer with high/low alarms and analog outputs

- Fluidwell F116 Differential / sum flow computer with analog and pulse outputs

-

Panel / Process Meters

- Fluidwell F070 Level indicator with very large digits

- Fluidwell D070 Level indicator with very large digits

- Fluidwell F073 Level monitor with one high / low alarm output

- Fluidwell F077 Level monitor with linearization and one high / low alarm output

- Fluidwell F170 Level monitor with high / low alarms and analog outputs

- Fluidwell F173 Level monitor with linearization, high / low alarms and analog outputs

- Fluidwell D073 Level monitor with one high / low alarm output

- Fluidwell D077 Level monitor with linearization and one high / low alarm output

- Fluidwell F074 Level / pump controller with one control output

- Fluidwell D074 Level / pump controller with one control output

- Panel / Process Meters

- Flow Rate / Totalisers

- Panel / Process Meters

-

Panel / Process Meters

- PD6060: PROVU Dual-Input Process Meter

- PD6080: PROVU Modbus Scanner with Dual Analog Inputs

- PD6081: PROVU Feet & Inches Modbus Scanner with Dual Analog Inputs

- PD6088: PROVU Modbus Scanner

- PD6089: PROVU Feet & Inches Modbus Scanner

- PD6100: PROVU Strain Gauge, Load Cell & mV Meter

- PD603: Sabre P Low-Cost Process Meter

- PD865 Snooper Modbus Serial Input Meter

- PD6000: PROVU Process Meter

- Panel / Process Meters

-

Panel / Process Meters

- PDA 2301-2322: Economical Plastic NEMA 4X Enclosures for 1/8 DIN Instruments

- PDA2407-2415: Plastic NEMA 4X Enclosures

- PDA2501-2522: Plastic NEMA 4X Enclosures

- PDA2601-2622: Stainless Steel NEMA 4X Enclosures

- PDA2701-2722: Steel NEMA 4 Enclosures

- PDA2801-2821: Low-Cost Plastic NEMA 4X Enclosure

- PDA2901: NEMA 4X Enclosures for ConsoliDator

- PDA3407-3414: Economical Plastic Fully Sealed Enclosures

- Panel / Process Meters

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F030 Field mount - Batch controller with one-stage control

- Fluidwell F130 Field mount - Batch controller with two-stage control and pulse output

- Fluidwell F131 Batch controller with 2-stage control, pulse & analog o/p in relation to flow rate

- Fluidwell F132 Field mount-Batch controller with two-stage control and receipt printer driver

- Fluidwell F136 Batch controller with 2-stage control, pulse & analog o/p in relation to process

- Fluidwell D030 DIN Panel mount - Batch controller with one stage control

- Fluidwell N410 DIN Panel mount - Batch controller

- Fluidwell 310 Batch controller with numerical keypad and two-stage control

- Fluidwell 313 Batch controller with numerical keypad and direct ticket printing

- Fluidwell 320 Batch controller with numerical keypad, multiple preset values

- Fluidwell 326 Tanker loading computer with numerical keypad

- Fluidwell 330 Dual batch controller with numerical keypad

- Fluidwell F133 Delivery controller / Dispenser with pump start and valve control

-

Panel / Process Meters

- Fluidwell F010 Flow rate indicator with very large digits

- Fluidwell F011 Totalizer with on-screen measuring units

- Fluidwell F012 Flow rate indicator / totalizer displays flow rate and total simultaneously

- Fluidwell D010 DIN Panel mount - Flow rate indicator with very large digits

- Fluidwell D011 DIN Panel mount - Totalizer with all-weatherproof front enclosure

- Fluidwell D012 Flow rate indicator / totalizer displays flow rate and total simultaneously

- Fluidwell F014 Flow rate indicator / totalizer with pulse output

- Fluidwell F016 Flow rate indicator / totalizer with linearization and pulse output

- Fluidwell F110 Flow rate indicator / totalizer with analog and pulse outputs

- Fluidwell F111 Dual input flow rate indicator / totalizer with two pulse outputs

- Fluidwell F115 Bi-directional flow rate indicator/totalizer with analog, pulse & flow direction o/p

- Fluidwell D014 Flow rate indicator / totalizer with pulse signal output

- Fluidwell F013 Flow rate monitor/totalizer with one high/low alarm output

- Fluidwell F113 Flow rate monitor / totalizer with high/low alarms, analog & pulse output

- Fluidwell F117 Totalizer monitor with high / low totalizer alarms and analog output

- Fluidwell F118 Flow rate monitor/totalizer with linearization, high/low alarms, analog & pulse o/p

- Fluidwell D013 DIN Panel mount - Flow rate monitor / totalizer with high / low alarm output

- Fluidwell F112 Flow rate indicator / totalizer with linearization, analog and pulse outputs

- Fluidwell D016 Flow rate indicator / totalizer with linearization and pulse signal output

- Fluidwell F018 Flow rate monitor/totalizer with linearization,pulse/alarm & analog o/p and HART

- Fluidwell E018 Explosion proof-Flow rate/totalizer with HART Communication

- Fluidwell E110 Flow rate indicator / totalizer with analog and pulse signal outputs

- Fluidwell E112 Flow rate indicator / totalizer with linearization, analog and pulse outputs

- Fluidwell F120 Flow rate controller with analog control output and high / low alarms

- Fluidwell F124 Ratio controller with analog control output and high / low alarms

- Fluidwell E115 Explosion-Proof Bi-directional Flow rate Indicator / Totalizer

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Inst Valves - Manifolds

- Tank Cleaning

- Process Protection

- Valve Positioners

- Analysers

- Signal Generator

- 4-20mA Set-Point Generator

- Large Display Field Mount Indicators

- Control Stations

- Lithium Battery

- Dosimeter

- Calibrator

DP Gauges / Indicating Switches

Cameron's BARTON® indicators are available for a variety of safe working pressures and differential pressure ranges. They are widely used for the measurement of differential pressure, flow rate, and liquid level applications.

Cameron's BARTON® differential pressure switches are available in a wide variety of safe working pressures and differential pressure ranges. Widely used in applications that require measurement of differential pressure, flow rate, and liquid level, they provide accuracy, narrow deadband, and repeatability of switch action at set point.

Cameron's BARTON® indicators and switches are actuated by a rupture-proof bellows differential pressure unit (DPU) with integral temperature compensation.

The indicating pointer traverses a 270-degree arc, providing excellent readability. It is driven by a precision-jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring. Zero/range adjustments can be made without removing the scale plate or pointer. Linearity adjustments are readily accessible after removal of the scale plate.

The indicating pointer traverses a 270-degree arc, providing excellent readability. It is driven by a precision-jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring.

|

The indicating pointer traverses a 270° arc, providing excellent readability. It is driven by a precision-jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring. Zero/Range adjustments can be made without removing the scale-plate or pointer. Linearity adjustments are readily accessible after removal of the scale-plate. |

|

CASES |

|

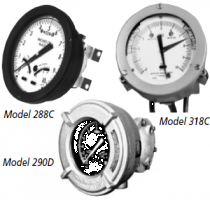

The standard case for indicators and switches is die-cast aluminum with a special epoxy black finish. Models 226C, 227C, and IT / ITS feature a NEMA-4 / IP65 rated case. The Model 232C has a 304 stainless steel case. The Models 290D, 322C, 752, 753, and select models of the IT / ITS Series have explosion-proof cases. |

|

MODEL TYPES |

|

Model 226C (w/224C DPU) A 3-inch (76 mm) indicator is a lightweight and compact instrument for use where panel space is at a premium. Model 227C (w/224C DPU) A 6-inch (152 mm) indicator that is ideally suited for tank level, flow, and pressure drop across filters. This model is also available in stainless steel (M227CS). Model 232C (w/224C DPU) An economical 6-inch (152 mm) DP indicator that is designed for use in applications where high accuracies are not required. Suitable for tank level, flowrate, and DP across filters applications. It features a 500 psi (34.5 bar) SWP Maximum and a 0-50" w.c. to 0-100 PSID (0-124 mbar to 6.9 bar) DP Range. The case and bezel are 304 SST. The housings are forged brass (steel and SST optional) with 1/4" x 1/4" NPT connections. The bellows are BeCu or 316 SST, with an Ethylene Glycol and Water Fill. The indicating accuracy is ±2.00 % of full scale. The unit can be pipe, wall, or panel mounted.

|

Barton switches are actuated by a rupture-proof bellows DPU with integral temperature compensation. The 224C DPU is a dual, liquid-filled, bellows designed to withstand repeated over-ranges equal to the safe working pressure of the housings without any change in calibration. The 224C SWP ranges from 500 psi (34 bar) to 6,000 psi (414 bar), NACE-compliant materials are available upon request.

|

The indicating pointer traverses a 270° arc, providing excellent readability. It is driven by a precision-jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring. Zero/Range adjustments can be made without removing the scale-plate or pointer. Linearity adjustments are readily accessible after removal of the scale-plate.

|

|

SWITCH CONTACTS |

|

Switch models can be ordered with 1 to 4 adjustable snap-acting type SPDT switches (DPDT and hermetically-sealed switches available as specials on selected models). Switches can be set for high, low, or both high and low on units with two or more contacts. Contacts are adjustable from 5 to 95% of full scale and are set with a control screw located flush with the scale-plate. Contacts can be set to open or close with increasing or decreasing DP — providing maximum flexibility.

Relays Some models can be ordered with 1 or 2 DPDT relays (mounted inside the case) for greater switching action and increased current handling capacity without the need for external mounting or wiring.

|

Cameron's BARTON® differential pressure switches are available in a wide variety of safe working pressures and differential pressure ranges. Widely used in applications that require measurement of differential pressure, flow rate, and liquid level, they provide accuracy, narrow deadband, and repeatability of switch action at set point. Standard Features • SWP to 10,000 PSI (689 bar) • BARTON DPU Sensor/Actuator • NEMA-4/IP65 and Explosion-proof Cases • Wide Selection of DP Ranges (including absolute, zero-center, and split ranges • Pulsation Dampening (selected models

BARTON DP switches are available in a wide variety of safe working pressures and differential pressure ranges. Widely used in applications that require measurement of differential pressure, flowrate, and liquid level, they provide accuracy, narrow deadband, and repeatability of switch action at set point.

Features

• SWP to 6,000 PSI (414 bar)

• BARTON DPU Sensor/Actuator

• NEMA-4/IP65 & Explosionproof Cases

• Wide Selection of DP Ranges (including absolute, zero-center,

and split ranges)

• Pulsation Dampening (selected models)

|

ACTUATING UNITS |

|

The indicator is actuated by a rupture-proof bellows differential pressure unit (DPU) with integral temperature compensation. The M199 DPU features dual, liquidfilled, bellows designed to withstand repeated overranges equal to the safe working pressure of the housings without a change in calibration.

|

|

INDICATING MECHANISM |

|

The indicating pointer traverses a 270° arc, providing excellent readability. It is driven by a precision jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring.

The movement has a micrometer screw for convenient range adjustments. Zero/range adjustments can be made without removing the scale plate or pointer. Linearity adjustments are readily accessible after removal of the scale plate.

|

|

SWITCH CONTACTS |

|

BARTON switches are available in configurations with 1 to 4 adjustable snap-action type SPDT switches, with DPDT and hermetically-sealed switches available as specials on selected models. Switches can be set for high or low, or both high and low on units with two or more contacts.

Chosen for their reliability under severe shock and vibration conditions, the contacts are adjustable from 5 to 95% of full scale range, and are set with a control screw located flush with the scale-plate. Contacts can be set to open or close (by reversing wires at terminal) with increasing or decreasing differential pressure – providing maximum flexibility.

Relays Some models can be ordered with one or two relays mounted inside the case. The addition of a relay allows greater flexibility of switching action and increased current handling capacity without the need for external mounting or wiring – important in applications that require explosion-proof housings.

|

|

CASES |

|

BARTON switches are available in indicating and blind case versions. The standard case is die-cast aluminum with a special baked epoxy black finish, which is NEMA-4/IP65 rated. Optional “S” version 316 Stainless Steel case is available for offshore/corrosive environments.

The optional explosion-proof case is rated for use in Class I, Div. 1, Groups B, C, & D areas.

|

|

SCALES |

|

All indicating scales can be graduated uniformly for measurement of differential pressure or liquid level, or square root for direct reading of flowrate. Special scales can be furnished for indicating liquid level in horizontal or non-uniform tanks. Scales are available in black with white lettering (standard) and in white with black lettering (optional, as shown).

|

|

M199 DPU ACTUATED UNITS |

|

Model 289A / 289AS / 289A NACE A 6-in. (152 mm) indicating switch that features a NEMA-4 case, operating pressure ratings up to 6,000 PSI (414 bar) and a differential pressure range from 0- 10-in. w.c. to 0-100 PSID (0-25 mbar to 0-6.9 bar).

Model 291B/291B NACE An explosionproof version of the M289A, it is housed in a CSA certified case rated for Class I, Div. 1, Groups B, C, & D areas.

|

|

SPECIFICATIONS |

|

M199 DPU Housings (Material/SWP) Forged Steel: 2500, 4500, & 6,000 PSI (172, 310, & 414 bar) 316 SST: 1,000 & 3,000 PSI (69 & 207 bar) Bellows Material: 316 SST & Inconel DP Ranges: 0-10-in. w.c. to 0-100 PSID (0-25 mbar to 0-6.9 bar) Switch (Indication Accuracy) SPDT: 0-10-in. w.c. to 0-349-in. w.c. ± 1.0% F.S. (0-25 mbar to 0- 867 mbar ± 1.0% F.S.) 0-350-in. w.c. to 0-100 PSID ± 1.25% F.S. (0-869 mbar to 0-6.9 bar ± 1.25% F.S.) DPDT: Add 1% to SPDT values Point of Actuation Accuracy: Add 1/2% to SPDT values Repeatability: 0.25% Switch Deadband: SPDT: ± 5.0% max. F.S. DP DPDT: ± 6.0% max. F.S. DP Temperature Limits: -40°F (-40°C) to +180°F (+82°C)

|

|

ORDERING INFORMATION |

|

When ordering, specify the following items: · Quantity · Model number · Housing pressure rating (SWP) · Housing material · Bellows material · Material contacting bellows · Differential pressure range · Number of switches (3 max.) · Switch type (SPDT or DPDT) · Switch detpoints (5-95%) · Optional relays (1 or 2) · Type of scale (uniform, square root) · Color of scale and scale lettering · Scale graduations

|

Cameron's BARTON® indicators are available for a variety of safe working pressures and differential pressure ranges. They are widely used for the measurement of differential pressure, flow rate, and liquid level applications. The indicator is actuated by a rupture-proof bellows differential pressure unit (DPU) with integral temperature compensation. The M199 DPU features dual, liquid-filled, bellows designed to withstand repeated overranges equal to the safe working pressure of the housings without a change in calibration. The indicating pointer traverses a 270 degree arc, providing excellent readability. It is driven by a precision jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring. The movement has a micrometer screw for convenient range adjustments. Zero/range adjustments can be made without removing the scale plate or pointer. Linearity adjustments are readily accessible after removal of the scale plate.

Cameron’s BARTON differential pressure indicators are available for a variety of safe working pressures and differential pressure ranges. They are widely used for the measurement of differential pressure, flow rate and liquid level applications.

Features

· BARTON differential pressure unit (DPU) sensor

· NEMA-4/IP65 cases

· Wide selection of differential pressure ranges (including absolute, zero-center and split ranges)

· Pulsation dampening

|

ACTUATING UNITS |

|

The indicator is actuated by a rupture-proof bellows DPU with integral temperature compensation. The M199 DPU features dual, liquid-filled bellows designed to withstand repeated over-ranges equal to the safe working pressure of the housings without a change in calibration.

|

|

INDICATING MECHANISM |

|

The indicating pointer traverses a 270-degree arc, providing excellent readability. It is driven by a precision-jeweled rotary movement that multiplies rotation of the torque tube through a gear and pinion to the pointer. The movement employs a thermally stable Ni-Span-C hair spring.

The movement has a micrometer screw for convenient range adjustments. Zero/range adjustments can be made without removing the scale plate or pointer. Linearity adjustments are readily accessible after removal of the scale plate.

|

|

CASES |

|

BARTON indicators are available in 6” (152 mm) dial size. The standard case is die-cast aluminum with a special baked epoxy black finish, which is NEMA-4/IP65 rated. An optional “S” version 316 stainless steel case is available for offshore/corrosive environments.

|

|

SCALES |

|

All indicating scales can be graduated uniformly for measurement of differential pressure, liquid level or square root for direct reading of flow rate. Special scales can be furnished for indicating liquid level in horizontal or non-uniform tanks. Scales are available in black with white lettering (standard) and in white with black lettering (optional, as shown).

|

|

M199 DPU ACTUATED UNITS |

|

Model 200A/200AS/200N* Features a 6” (152 mm) indicator with a built-in adjustable pulsation dampener for direct control of response time.

Note: For NACE applications, M200N uses a M199N DPU.

|

|

SPECIFICATIONS |

|

M199 DPU housings (material/SWP) Forged steel: 2500, 4500 and 6000 psi (172, 310 and 414 bar) 316 SST: 1000, 3000 and 6000 psi (69, 207 and 414 bar) Aluminum: 1000 psi (69 bar) Bellows material: 316 SST and Inconel® Differential pressure ranges: 0 to 10 inches wc to 100 psid (25 mbar to 6.9 bar)

200A/200AS Indicator Accuracy (differential pressure range): 10 inches wc to 349 inches wc ± 0.5% FS (25 mbar to 867 mbar ± 0.5% FS) 350 inches wc up to 100 psid ± 0.75% FS (869 mbar to 6.9 bar ± 0.75% FS) Repeatability: 0.25% Temperature limits: -40° F to 180° F (-40° C to 82° C)

|

|

ORDERING INFORMATION |

|

When ordering, specify the following items: · Quantity · Model number · Housing pressure rating (SWP) · Housing material · Bellows material · Material contacting bellows · Differential pressure range · Type of scale (uniform, square root) · Color of scale and lettering · Mounting (pipe, wall, flush panel)

|

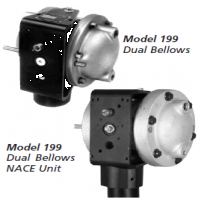

Cameron\\\'s BARTON® differential pressure units (DPUs) serve as actuating units for a wide variety of instruments. All models feature rupture-proof bellows. Each DPU consists of a bellows unit assembly (BUA) and removable pressure housings. Within the BUA, flexible bellows are secured to a centerplate. In dual-bellows models, the movable bellows are rigidly connected by a dual valve stem that passes through the centerplate.

Barton® Differential Pressure Units (DPUs) serve as actuating units for a wide variety of instruments. All models feature Barton’s® rupture-proof bellows.

Each DPU consists of a Bellows Unit Assembly (BUA) and removable pressure housings. Within the BUA, flexible bellows are secured to a centerplate. In dual-bellows models, the movable bellows are rigidly connected by a dual valve stem that passes through the centerplate. Valve seats, in the centerplate passage, form a seal with the valves. Contacting the valve stem in the centerplate is a drive arm pivoted on the end of a sealed torque tube.

The bellows is filled with a clean, noncorrosive, low-freezing point liquid. A range spring assembly provides tension against applied pressures. In operation, pressure is applied to both sides of the bellows. Any difference in pressure causes the bellows to move until the spring effect (range springs) balances out the force. The linear motion of the bellows (proportional to the DP) is transmitted as a rotary motion through the torque tube.

In dual-bellows units, if the bellows are subjected to a DP greater than the unit’s DP rating, a valve closes and “traps” the fill liquid in the bellows — fully supporting the bellows and preventing rupture. Since opposing valves are used, full protection is provided in either direction.

- Housing/Centerplate: Forged Steel AISI C1018

- Bolts: AISI 4140, per ASTM A.320 L7M

- Housing O-rings: Viton

- Bellows: 316L SST

- Range Springs: Inconel or Elgiloy

- Torque Tube Material: Monel

The BARTON® 224C DPU is a lightweight compact sensor that incorporates a rupture-proof bellows in a common-head design housing. It has an exceptionally fast response time, is self draining, and has built-in temperature compensation.

The BARTON® 224C DPU is a lightweight compact sensor that incorporates a rupture-proof bellows in a common-head design housing. It has an exceptionally fast response time, is self draining, and has built-in temperature compensation.

The 224C DPU consists of a bellows unit assembly (BUA) and removable pressure housings. within the BUA, flexible bellows are secured to a centerplate. In dual-bellows models, the movable bellows are rigidly connected by a dual valve stem that passes through the centerplate. Valve seats, in the centerplate passage, form a seal with the valves. Contacting the valve stem in the centerplate is a drive arm pivoted on the end of a sealed torque tube. The bellows is filled with a clean, noncorrosive, low-freezing point liquid. A range spring assembly provides tension against applied pressures.

In operation, pressure is applied to both sides of the bellows. Any difference in pressure causes the bellows to move until the spring effect (range springs) balances out the force. The linear motion of the bellows (proportional to the DP) is transmitted as a rotary motion through the torque tube.

In dual-bellows units, if the bellows are subjected to a DP greater than the unit's DP rating, a valve closes and "traps" the fill liquid in the bellows - fully supporting the bellows and preventing rupture. Since opposing valves are used, full protection is provided in either direction.