- Rosemount Tank Gauging

- Cameron

- Leakwise

- Siemens

- Precision Digital

- Scanjet

- Labkotec

- Enerac

- Contrec

- Berthold

- BWB Controls / Axelson

- Anderson Greenwood / AGCO

- ITT NeoDyn

- Graphic Controls

- Fuji Electric

- Fluidwell

- Xylem McDonnell Miller

- PKP Process Instrumentation

- Noshok

- Temperature Sensors

- Lauris Technologies

- Hitrol

- Radioactive Services In

- CS Instruments

- Bopp & Reuther

- RAE Systems, Inc.

- Emerson

- Supmea

-

Flow

-

Flow

- Paddle Type Flow Switch

- Paddle type flow switch with cable connection

- Paddle-bellows flow switch for liquids, with variable switching point

- Paddle-bellows flow meter and switch for liquids

- Flap Flowmeter and switch for low viscosity liquids

- Flap Flowmeter

- Paddle-bellows type flow switch with micro switch

-

Flow

- Flow Indicator with Wiper

- Rotor-type Flow Indicator

- Flow Indicator with Turbine

- Flow Indicator with Flanges

- Flow Indicator with Flap and Scale

- Ball type Flow Indicator

- Flow Indicator with Threaded Connection

- DG11 Flow Sight Glass with Flanged Connections

- Miniature Variable Area Flow meter and Switch

- Variable area flowmeter and switch with glass measuring tube

- Plastic Variable Area Flowmeter

- Float-Type Flow Meter For low flow volumes Compact construction

- Variable Area Flowmeter With Flange Connection, Insensitive To Viscosity Changes

- Piston Type Flow Switch for Low Flow Applications

- Flow

- Flow

- Flow

-

Flow

- SIEMENS SITRANS FUS 1010 (Standard) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUE 1010 (Energy) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUP 1010 (Portable) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUG 1010 (Gas) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUT 1010 (Liquid) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FUT 1010 (Gas) Ultrasonic Clamp-On Flowmeter

- SIEMENS SITRANS FST 020 (Basic) Ultrasonic clamp-on flowmeters

-

Flow

- SIEMENS SITRANS FM MAG 3100 Flow Meter - Electromagnetic (sensor)

- SIEMENS SITRANS FM MAG 5100W Flow Meter - Electromagnetic (sensor)

- SIEMENS SITRANS FM MAG 1100 F Electromagnetic Flowmeter

- SIEMENS SITRANS FM MAG 1100 Electromagnetic Flowmeter

- SIEMENS SITRANS FM MAG 3100P Electromagnetic Flowmeter (Sensor)

- SIEMENS SITRANS FM MAG 5100 Ex d Electromagnetic Flowmeter(transmitter)

- SIEMENS SITRANS FM MAG 6000 Electromagnetic Flowmeter (transmitter)

- SIEMENS SITRANS FM MAG 6000 I/6000 I Ex de ELectromagnetic Flowmeter (transmitter)

- SIEMENS SITRANS FM Verificator Electromagnetic Flowmeter (Equipment tester for flowmeter)

- Flow

-

Flow

- SIEMENS SITRANS FCT 030 Coriolis/Density Flowmeter (Transmitter)

- SIEMENS SITRANS FC MASS 6000 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC MASS 6000 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SIFLOW FC 070 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC S400 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC S200 Ex d Coriolis/Density Flowmeter(Sensor)

- SIEMENS SITRANS FC MC 2 DN 50-150/ DN 20-80 (Hygienic) Ex d Coriolis/Density Flowmeter(sensor)

- SIEMENS SIEMENS SITRANS FC MASS 2100 DI 3-40 Ex d Coriolis/Density Flowmeter(sensor)

- SIEMENS SITRANS FC300 DN 4 Ex d Coriolis/Density Flowmeter(transmitter)

- SIEMENS SITRANS FC MASS 2100 DI 1.5 Ex d Coriolis/Density Flowmeter(sensor)

- Flow

-

Flow

- Liquid Flow Switches

- General Purpose Liquid Flow Switches FS 251 and FS 254

- FS 4-3T General Purpose Liquid Flow Switches

- FS 4-3 General Purpose Liquid Flow Switches

- FS 6-W High Sensitivity Liquid Flow Switches

- FS 1-W High Sensitivity Liquid Flow Switches

- FS 5 General Purpose Liquid Flow Switches

- FS 6 High Sensitivity Liquid Flow Switches

- FS 7-4E General Purpose Liquid Flow Switches

- FS 7-4 Industrial Liquid Flow Switches

- FS 7-4W Industrial Liquid Flow Switches

- FS 8-W Industrial Liquid Flow Switches

- Flow

- SIEMENS SITRANS DP Flow Transmitter

- Flow

- Flow

- Flow

-

Flow

- Low Water Cut off- Mechanical for Steam Boiler

- RB-122-E-Low Water Cut-Off

- RB-24E-Low Water Cut-Off

- RBT-3000 LWCO and Fuel Economizer

- RS-1-HP High Pressure Remote Sensor

- RS-1-LP Low Pressure Remote Sensor

- Series 21/221 Make-Up Water Feeders

- Series 25-A Make-Up Water Feeder

- Series 27-W Valve

- Series 47-2/247-2 Mechanical Water Feeder/LWCO

- Series 42S LWCO/Pump Controllers

- Series 47/247 Water Feeders

- Series 51/51-2 Mechanical Water Feeders/ LWCO

- Series 53/53-2 Mechanical Water Feeders/ LWCO

- Flow

- Cameron Flow Analysers

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Flow

- Restriction Orifice

- Flow

- Flow

- Flow

- Electromagnetic Flow Meters

- Flow

- Cavitating Venturi

- Flow

- Flow

- Flow

- Flow

- Paddle Switches

- Flow

- Flow

- Bopp and Reuther coriolis flow meter

-

Flow

- Level

-

Pressure

- Precision Digital Pressure Gauges

- Pressure

- Pressure

- Pressure

- Pressure

-

Pressure

- 151P Low Differential Set Points (Explosion Proof)

- 152P Ultra Low System Pressure (Weather Proof)

- 160P Mid Range System Pressure (Weather Proof)

- 152P Ultra Low System pressure (Explosion Proof)

- 151P Low Differential Set Points (Explosion Proof)

- 160P Mid Range System Pressure (Explosion Proof)

- 162P High System Pressure (Explosion Proof)

- Pressure

- Pressure

-

Pressure

- 100P Internally Adjustable (Weather Proof)

- 101P Externally Adjustable (Weather Proof)

- 105P/105PP Minature Pressure Switch (Weather Proof)

- 110P Low Pressure Range (Weather Proof)

- 115P/115PP Built-To-Order (Weather Proof)

- 125P Higher Range Pneumatic Applications ( Weather Proof)

- 130P Adjustable Thru Port Cap-Pressure (Weather Proof)

- 131P Adjustable With Selectable Deadband-pressure (Weather Proof)

- 132P Pneumatic Or Low Impulse Hydrauic (Weather Proof)

- 142P Div 1&2 Hermetic-Ultra Low Range (Weather Proof)

- 200P Hydraulic Service-Internally Adjustable (Weather Proof)

- 201P Hydraulic Service-Externally Adjustable (Weather Proof)

- 225P High Pressure Hydraulic Applications (Weather Proof)

- 231P Adjustable Hydraulic Switch (Weather Proof)

- 232P High Pressure or High Impulse Hydraulic (Weather Proof)

- 100P Div 2/Terminal Strip (Explosion Proof)

- 100P Div 1 W/Terminal Strip ( Exposion Proof)

- 100P Div 1 & 2 hermetic (Explosion Proof)

- 110P Div 2 W/Terminal Strip- Low Range ( Explosion proof)

- 110P Div 1& 2 Hermetic- Low Range (Explosion proof)

- 112P ANSI Flanged Pessure Switch (Explosion Proof)

- 115P/115PP Build-To-Order Set Point (Explosion Proof)

- 122P CPI Pressure Switch (Explosion Proof)

- 123P Flush Welded Diaphragm (Explosion Proof)

- 125P higher Range Pneumatic Applications (Explosion Proof)

- 130P AdjustableThru Port Cap (Explosion Proof)

- 131PX Adjustable Selectable Deadband (Explosion Proof)

- 132P Universal Prssure Switch (Explosion Proof)

- 200P Div 1&2 Hermetic-hydraulic (Explosion Proof)

- 225P High Pressure hydraulic Applications (Explosion Proof)

- 231P Agjustable-Hydraulic (Explosion Proof)

- 232P High Pressure-Hydraulic (Explosion Proof)

-

Pressure

- 142P Ultra Low Vacuum (Explosion Proof)

- 142P Ultra LowVacuum (Weather Proof)

- 180P High System Pressure (Weather Proof)

- 181P Compact Vacuum Switch (Weather Proof)

- 182P Adjustabe Thru Port Cap (Weather Proof)

- 142P Ultra Low Vacuum (Explosion Proof)

- 181P Compact Vacuum (Explosion Proof)

- 182P Adjustable Thru Port Cap-Vacuum (Explosion Proof)

- Pressure

- Pressure

- Pressure

- Pressure

- Pressure

- Pressure

- Temperature

-

Tank Gauging System

- Tank Gauging System

-

Tank Gauging System

- Rosemount 5900C Radar Level Gauge

- Rosemount 5900S Radar Level Gauge

- Rosemount 5300 GWR Level Transmitters

- Rosemount 5400 Radar Level Transmitter

- Rosemount 565/566 Multiple Spot or Average Temperature Sensor

- Rosemount 2240S Multi-input Temperature Transmitter

- Rosemount 2410 Tank Hub

- Rosemount 2160 Field Communication Unit

- Rosemount 2230 Graphical Field Display

- Rosemount 2460 System Hub

- Rosemount 3051S Pressure Transmitter

- Rosemount 2120 Vibrating Fork Liquid Level Switch

- Rosemount 2130 High Temperature Level Switch SIL2

- SmartPower Solutions

- Tank Gauging System

- Tank Gauging System

-

Tank Gauging System

- RTG 3920 Horn Antenna Gauge

- RTG 3930 Parabolic Antenna Gauge

- RTG 3950 Still-pipe Array Antenna Gauge

- RTG 3960 LPG/LNG Gauge

- DAU2100 Data Acquisition Unit

- RDU40 Remote Display Unit

- MST - Multiple Spot or Average Temperature Sensor

- WLS - Water Level Sensor

- FCU 2160 - Field Communication Unit

- FBM 2180 - Field Bus Modem

-

Radioactive Instruments

- Radioactive Instruments

- Radioactive Instruments

-

Radioactive Instruments

- BERTHOLD LB565 Microwave Radiation Brix Measurement and Concentration Measurement

- BERTHOLD LB 566/567 Microwave Analyzer (Concentration and Water Content Measurement)

- BERTHOLD Carbon Content in Fly Ash (Combustion Analyzer)

- BERTHOLD MicroPolar Moist LB 568 System Highlights (Radioactive and Microwave measurement)

- BERTHOLD LB 350 Radiometric Moisture Measurement

- Radioactive Instruments

- Radioactive Instruments

- Recorders

-

Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F050 Pressure indicator with very large digits with on-screen measuring units

- Fluidwell D050 Pressure indicator with very large digits

- Fluidwell F151 Dual input pressure indicator with separate engineering units for each input

- Fluidwell F053 Pressure monitor with one high / low alarm output

- Fluidwell F153 Pressure monitor with high / low alarms and analog outputs

- Fluidwell D053 Pressure monitor with one high / low alarm output

- Fluidwell F143 Temperature monitor with high / low alarms and analog outputs

-

Panel / Process Meters

- Fluidwell F040 Temperature indicator with very large digits

- Fluidwell D040 Temperature indicator with very large digits

- Fluidwell F141 Dual input temperature indicator with separate engineering units for each input

- Fluidwell F043 Temperature monitor with one high / low alarm output

- Fluidwell D043 Temperature monitor with one high / low alarm output

-

Panel / Process Meters

- Fluidwell F090 General purpose indicator input loop powered with very large digits

- Fluidwell D090 General purpose indicator input loop powered with very large digits

- Fluidwell F193 Modbus display with alarms, control and analog outputs

- Fluidwell F195 Valve Position Indicator VPI for hydraulic systems

- Fluidwell F197 Set-point generator with temperature input, alarms and analog outputs

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F126-EL Flow computer with temperature compensation for corrected liquid volume

- Fluidwell F126-EG Flow computer with temp & pressure compensation for corrected gas volume

- Fluidwell F127 Differential flow computer with temperature compensation for corrected liquid

- Fluidwell F114 Ratio monitor / totalizer with high/low alarms and analog outputs

- Fluidwell F116 Differential / sum flow computer with analog and pulse outputs

-

Panel / Process Meters

- Fluidwell F070 Level indicator with very large digits

- Fluidwell D070 Level indicator with very large digits

- Fluidwell F073 Level monitor with one high / low alarm output

- Fluidwell F077 Level monitor with linearization and one high / low alarm output

- Fluidwell F170 Level monitor with high / low alarms and analog outputs

- Fluidwell F173 Level monitor with linearization, high / low alarms and analog outputs

- Fluidwell D073 Level monitor with one high / low alarm output

- Fluidwell D077 Level monitor with linearization and one high / low alarm output

- Fluidwell F074 Level / pump controller with one control output

- Fluidwell D074 Level / pump controller with one control output

- Panel / Process Meters

- Flow Rate / Totalisers

- Panel / Process Meters

-

Panel / Process Meters

- PD6060: PROVU Dual-Input Process Meter

- PD6080: PROVU Modbus Scanner with Dual Analog Inputs

- PD6081: PROVU Feet & Inches Modbus Scanner with Dual Analog Inputs

- PD6088: PROVU Modbus Scanner

- PD6089: PROVU Feet & Inches Modbus Scanner

- PD6100: PROVU Strain Gauge, Load Cell & mV Meter

- PD603: Sabre P Low-Cost Process Meter

- PD865 Snooper Modbus Serial Input Meter

- PD6000: PROVU Process Meter

- Panel / Process Meters

-

Panel / Process Meters

- PDA 2301-2322: Economical Plastic NEMA 4X Enclosures for 1/8 DIN Instruments

- PDA2407-2415: Plastic NEMA 4X Enclosures

- PDA2501-2522: Plastic NEMA 4X Enclosures

- PDA2601-2622: Stainless Steel NEMA 4X Enclosures

- PDA2701-2722: Steel NEMA 4 Enclosures

- PDA2801-2821: Low-Cost Plastic NEMA 4X Enclosure

- PDA2901: NEMA 4X Enclosures for ConsoliDator

- PDA3407-3414: Economical Plastic Fully Sealed Enclosures

- Panel / Process Meters

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Fluidwell F030 Field mount - Batch controller with one-stage control

- Fluidwell F130 Field mount - Batch controller with two-stage control and pulse output

- Fluidwell F131 Batch controller with 2-stage control, pulse & analog o/p in relation to flow rate

- Fluidwell F132 Field mount-Batch controller with two-stage control and receipt printer driver

- Fluidwell F136 Batch controller with 2-stage control, pulse & analog o/p in relation to process

- Fluidwell D030 DIN Panel mount - Batch controller with one stage control

- Fluidwell N410 DIN Panel mount - Batch controller

- Fluidwell 310 Batch controller with numerical keypad and two-stage control

- Fluidwell 313 Batch controller with numerical keypad and direct ticket printing

- Fluidwell 320 Batch controller with numerical keypad, multiple preset values

- Fluidwell 326 Tanker loading computer with numerical keypad

- Fluidwell 330 Dual batch controller with numerical keypad

- Fluidwell F133 Delivery controller / Dispenser with pump start and valve control

-

Panel / Process Meters

- Fluidwell F010 Flow rate indicator with very large digits

- Fluidwell F011 Totalizer with on-screen measuring units

- Fluidwell F012 Flow rate indicator / totalizer displays flow rate and total simultaneously

- Fluidwell D010 DIN Panel mount - Flow rate indicator with very large digits

- Fluidwell D011 DIN Panel mount - Totalizer with all-weatherproof front enclosure

- Fluidwell D012 Flow rate indicator / totalizer displays flow rate and total simultaneously

- Fluidwell F014 Flow rate indicator / totalizer with pulse output

- Fluidwell F016 Flow rate indicator / totalizer with linearization and pulse output

- Fluidwell F110 Flow rate indicator / totalizer with analog and pulse outputs

- Fluidwell F111 Dual input flow rate indicator / totalizer with two pulse outputs

- Fluidwell F115 Bi-directional flow rate indicator/totalizer with analog, pulse & flow direction o/p

- Fluidwell D014 Flow rate indicator / totalizer with pulse signal output

- Fluidwell F013 Flow rate monitor/totalizer with one high/low alarm output

- Fluidwell F113 Flow rate monitor / totalizer with high/low alarms, analog & pulse output

- Fluidwell F117 Totalizer monitor with high / low totalizer alarms and analog output

- Fluidwell F118 Flow rate monitor/totalizer with linearization, high/low alarms, analog & pulse o/p

- Fluidwell D013 DIN Panel mount - Flow rate monitor / totalizer with high / low alarm output

- Fluidwell F112 Flow rate indicator / totalizer with linearization, analog and pulse outputs

- Fluidwell D016 Flow rate indicator / totalizer with linearization and pulse signal output

- Fluidwell F018 Flow rate monitor/totalizer with linearization,pulse/alarm & analog o/p and HART

- Fluidwell E018 Explosion proof-Flow rate/totalizer with HART Communication

- Fluidwell E110 Flow rate indicator / totalizer with analog and pulse signal outputs

- Fluidwell E112 Flow rate indicator / totalizer with linearization, analog and pulse outputs

- Fluidwell F120 Flow rate controller with analog control output and high / low alarms

- Fluidwell F124 Ratio controller with analog control output and high / low alarms

- Fluidwell E115 Explosion-Proof Bi-directional Flow rate Indicator / Totalizer

- Panel / Process Meters

- Panel / Process Meters

-

Panel / Process Meters

- Oil / Sludge Alarm

- Tank Cleaning

- Process Protection

- Valve Positioners

- Analysers

- Inst Valves - Manifolds

- Dosimeter

- Lithium Battery

- Calibrator

- Signal Generator

- 4-20mA Set-Point Generator

- Large Display Field Mount Indicators

- Control Stations

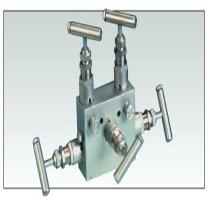

Differential Pressure Manifolds

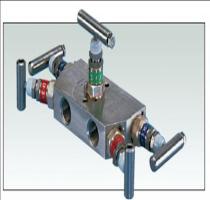

The M1 is a three-valve manifold designed to mount to the signal lines and instrument when the instrument has connections different than 21⁄8-inches [54 mm] between signal taps such as recording orifice meters, small differential pressure indicators and some differential pressure switches

The M1 is a three-valve manifold designed to mount to the signal lines and instrument when the instrument has connections different than 21⁄8-inches [54 mm] between signal taps such as recording orifice meters, small differential pressure indicators and some differential pressure switches.In these applications, the manifold is often supported by the signal lines but may be AGCO Mount supported (-AM). The M1 manifold is available with an integral metal seat or with various replaceable, roddable soft seats. The valve orifice is 3/16-inch [4.8 mm] diameter. The M110 manifold is a high pressure version of the M1 and is available in 316 SS with integral seats.

The MM1 is a miniature three-valve manifold for applications requiring remote mounting from the instrument. Made in CS, 316 SS, or brass, the MM1 features O-ring or packed bonnets with soft or metal seats.

The MM1 is a miniature three-valve manifold for applications requiring remote mounting from the instrument. Made in CS, 316 SS, or brass, the MM1 features O-ring or packed bonnets with soft or metal seats. This mini-manifold features a unique valve seat which can be converted from soft to hard by simply removing two insert washers. No other parts are required. Used to set or reset differential pressure switches during initial plant start-up. Also used in assemblies for portable differential pressure test equipment used for any miniature differential pressure measuring device.

Designed for remote mounting an instrument via threaded process and instrument connections, the A22N has two block valves, an equalizer valve and two instrument side vent/calibrate valves.

Designed for remote mounting an instrument via threaded process and instrument connections, the A22N has two block valves, an equalizer valve and two instrument side vent/calibrate valves. Process and instrument side connections are available either 1/4-inch or 1/2-inch threaded. Vent connections are threaded 1/4-inch on all manifolds and provided with blanking plugs. The instrument connections are positioned on 21/8-inch [54 mm] centers but can easily be adapted to suit instruments with other center-to-center dimensions via screwed fittings. Suitable for pressures of up to 6000 psig [414 barg] and temperatures of up to 1000°F [538°C].

The M3A Equalizer Manifold is designed for use with differential pressure transmitters where low-cost direct coupling is desired and piping specifications require individual block valves.

The M3A Equalizer Manifold is designed for use with differential pressure transmitters where low-cost direct coupling is desired and piping specifications require individual block valves. The valve is Teflon® -packed and uses a self-aligning SS ball seat. This single valve serves to equalize the transmitter. The M3A fits between the transmitter and the 2-bolt flanges (futbols). For complete mounting, each manifold package includes two Teflon® or GRAFOIL® gaskets and four 7/16-inch – 20 x 21/2-inch zinc cobalt plated alloy steel bolts.

Our M4 Manifold is a three-valve unit designed for mounting on differential pressure transmitters having 21/8-inch [54 mm] center-to-center connections. For direct or remote mounting, the M4A permits the transmitter’s futbol flanges to connect the process signal lines to the manifold directly, with either 1/2-inch pipe or tubing connections.

Our M4 Manifold is a three-valve unit designed for mounting on differential pressure transmitters having 21/8-inch [54 mm] center-to-center connections. For direct or remote mounting, the M4A permits the transmitter’s futbol flanges to connect the process signal lines to the manifold directly, with either 1/2-inch pipe or tubing connections. It contains two main block valves and an equalizing valve. For close or remote mounting, the M4T Manifold is used in applications where direct coupling to orifice flanges is not desired. On the instrument side, the M4T bolts directly to the transmitter. On the process side, two 1/2-inch NPT or AGCOTube connections are provided for piping or tubing into the flange taps.

Our M45A manifold is a three-valve unit with 3/8-inch [9.5 mm] orifice block valves designed for mounting on differential pressure transmitters having 21/8-inch [54 mm] center-to-center connections.

Our M45A manifold is a three-valve unit with 3/8-inch [9.5 mm] orifice block valves designed for mounting on differential pressure transmitters having 21/8-inch [54 mm] center-to-center connections. For direct or remote mounting, the M45A permits the transmitter’s futbol flanges to connect the process signal lines to the manifold directly, with either 1/2-inch pipe or tubing connections. It contains two main block valves and an equalizing valve. Same as M4A except bonnet to accommodate 3/8-inch [9.5 mm] orifice soft seat block valves and metal seat equalizer valve.

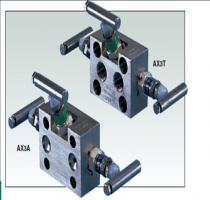

The AX3 is a three-valve manifold designed for direct mounting to standard differential pressure transmitters. Lightweight and compact, the manifolds enable instrument operation, isolation and zeroing in a single unit.

The AX3 is a three-valve manifold designed for direct mounting to standard differential pressure transmitters. Lightweight and compact, the manifolds enable instrument operation, isolation and zeroing in a single unit. Process connections are available either threaded 1/4- and 1/2-inch NPT or flanged to accept standard futbol flanges. Suitable for pressures of up to 6000 psig [414 barg] and temperatures of 1000°F [538°C]. AX3 is available metal seated with the option of Teflon® or Graphite stem packing.

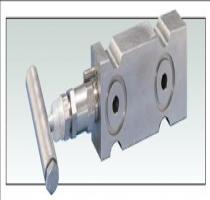

The M20 Manifold is a rotary-positioned differential pressure transmitter manifold. It uses a dual-rotary element with passages cut to perform the functions of a doubleblock- bleed manifold, with single handle actuation.

The M20 Manifold is a rotary-positioned differential pressure transmitter manifold. It uses a dual-rotary element with passages cut to perform the functions of a doubleblock- bleed manifold, with single handle actuation. The M20 ensures correct valve sequencing every time the manifold is manipulated from RUN-to-ZERO-to-OFF, or from OFF-to-ZERO-to-RUN.

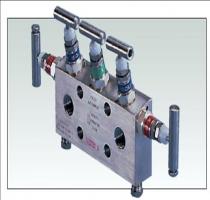

The M24 is a five-valve manifold designed for direct mounting to differential pressure transmitters. Lightweight and with compact dimensions, M24 manifolds enable instrument operation, isolation, zeroing and venting in a single unit.

The M24 is a five-valve manifold designed for direct mounting to differential pressure transmitters. Lightweight and with compact dimensions, M24 manifolds enable instrument operation, isolation, zeroing and venting in a single unit. Manufactured from a precision casting with two block valves, an equalize valve and two instrument vent/calibrate valves, the M24 is coupled directly to differential pressure transmitters via standard instrument flanged connections on 21/8-inch [54 mm] centers. (Non-standard instrument centers are also available). Process connections are available threaded or flanged to accept standard futbol flanges. Vent connections are threaded 1/4-inch on all manifolds and provided with vent plugs as standard. Suitable for pressures of up to 6000 psig [414 barg] and temperatures of up to 1000°F [538°C]. M24 is available with a metal seat and the option of Teflon® or GRAFOIL® stem packing.

The A26 is a five-valve manifold designed for mounting to differential pressure transmitters. Lightweight and with compact dimensions, A26 manifolds enable instrument operation, isolation, zeroing and venting in a single unit.

The A26 is a five-valve manifold designed for mounting to differential pressure transmitters. Lightweight and with compact dimensions, A26 manifolds enable instrument operation, isolation, zeroing and venting in a single unit. The A26 is coupled directly to differential pressure transmitters via standard instrument side flanged connections on 21/8-inch [54 mm] centers. Process connections are available threaded 1/4-inch and 1/2-inch NPT. Vent connections are threaded 1/4-inch NPT on all manifolds and provided with vent plugs as standard. Suitable for pressures of up to 6000 psig [414 barg] and temperatures of up to 1000°F [538°C], A26 is available with a metal seat and the option of Teflon® or Graphite stem packing.

The MDP is a five valve manifold designed for direct mounting to differential pressure transmitters. Lightweight and with compact dimensions, MDP manifolds enable instrument operation, isolation, zeroing and venting in a single unit.

The MDP is a five valve manifold designed for direct mounting to differential pressure transmitters. Lightweight and with compact dimensions, MDP manifolds enable instrument operation, isolation, zeroing and venting in a single unit. Manufactured with two block valves, an equalize valve and two instrument vent/calibrate valves, the MDP is coupled directly to differential pressure transmitters via standard instrument flanged connections on 21/8-inch [54 mm] centers. (Non-standard instrument centers are also available). Process connections are available threaded or flanged to accept standard futbol flanges. Vent connections are threaded 1/4-inch on all manifolds and provided with vent plugs as standard. Suitable for pressures of up to 6000 psig [414 barg] and temperatures of up to 1000°F [538°C]. MDP is available with a metal seat and the option of Teflon® or GRAFOIL® stem packing.

The DPM is a five-valve manifold designed for remote mounting to differential pressure transmitters. Lightweight and with compact dimensions, DPM manifolds enable instrument operation, isolation, zeroing and venting in a single unit.

The DPM is a five-valve manifold designed for remote mounting to differential pressure transmitters. Lightweight and with compact dimensions, DPM manifolds enable instrument operation, isolation, zeroing and venting in a single unit. Two block valves, one equalizer valve and two vent/test valves are combined into a compact unit designed for rack or pipe-stand mounting. Two 1/4-inch FNPT vent/test ports are provided for ease of venting and field calibration of the instrument.

The MM5 is a five-valve miniature manifold designed for instrument installations where space is restricted. Lightweight and with compact dimensions, MM5 manifolds are designed for flow metering and differential pressure transmitters to enable instrument operation, isolation, zeroing and venting in a single unit.

The MM5 is a five-valve miniature manifold designed for instrument installations where space is restricted. Lightweight and with compact dimensions, MM5 manifolds are designed for flow metering and differential pressure transmitters to enable instrument operation, isolation, zeroing and venting in a single unit. Designed for remote mounting from the instrument via 1/4-inch NPT threaded instrument and process connections, the MM5 uses H5 miniature bonnets which are available with metal or soft seats. This versatile design can be converted to soft seats simply by fitting a soft seat and flow washer. Available in stainless steel only MM5 has two block valves, an equalizer valve and two vent valves. Suitable for pressure up to 6000 psig [414 barg] and temperatures of up to 500°F [260°C], MM5 has a Teflon® stem packing and the choice of Delrin®, PCTFE or PEEK soft seats.